BESIDES QUALITY CONTROL: WHAT STATISTICS CAN TELL ABOUT YOUR PRODUCTION

The main reason why a company decides to adopt automatic machines for quality control is undoubtedly to provide production lots free of defective parts and guarantee its customers products with the highest quality possible.

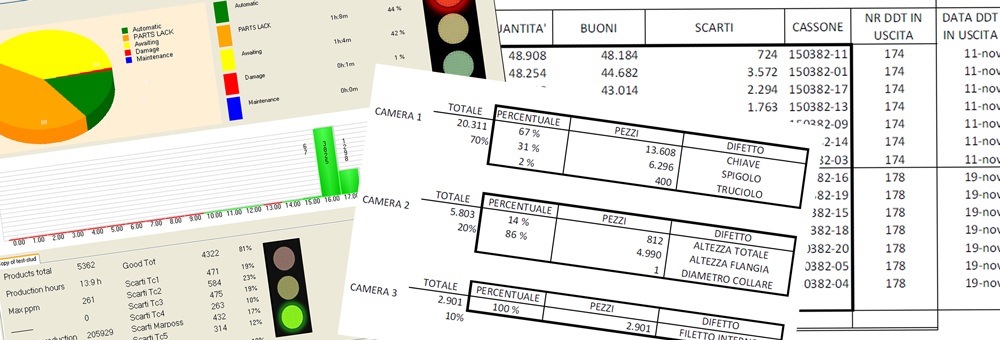

There is however a second reason about getting an inspection machine that might lead to big advantages not only in terms of return of the image, given by the verified reliability of the pieces marketed, but also in terms of saving and reduction of production costs. Great benefits can indeed be achieved by analyzing the reports on the quality of production. For this purpose Champs has implemented its machines with software tools able to bring comprehensive statistics on type and number of defects in the production lots. The parameters to be controlled are always agreed with the customer according to the type of component. The Sorting Machine during its work cycle stores all the data in a database and produces reports on its activity (the statistics relate to both the machine’s performances and data about the controlled lots). Data analysis can be used to detect downstream the causes of the most frequent defects and allow any interventions to improve the production and to reducing wastage.

A frequent case is that of components affected by imperfections in the heat treatment or galvanic coating; processes where even modest alterations in the bath formulation or in temperature can lead to production lots with large percentages of scrap pieces. In these cases a prompt detection of a frequent defect can enable to find out with greater ease the cause of the problem and facilitate resolution in a short time.