DIMENSIONAL CONTROLS

Trough Optical and Laser Inspection units every kind of dimensional parameter can be checked with tolerances between 1 and 10µm.

read more

CRACKS AND FLAWS

The quality controls, through Optical or Eddy Currents inspection units, allow to spot on each piece the smallest defect capable of compromising hardness and functionality.

read more

FUNCTIONALITY TESTS

The sorting machines can be equipped with special units designed to phisically check the actual functionality of the mechanical component

read moreDIMENSIONAL CONTROLS

The tolerance control and dimensional conformity are the first requirements to boast high-quality productions in the fasteners industry. Champs provides machines able to carry out compliance inspections on any dimensional parameter required by the customer on its pieces.

The checking stations for dimensional parameters mounted on our machines are:

The checking stations for dimensional parameters mounted on our machines are:

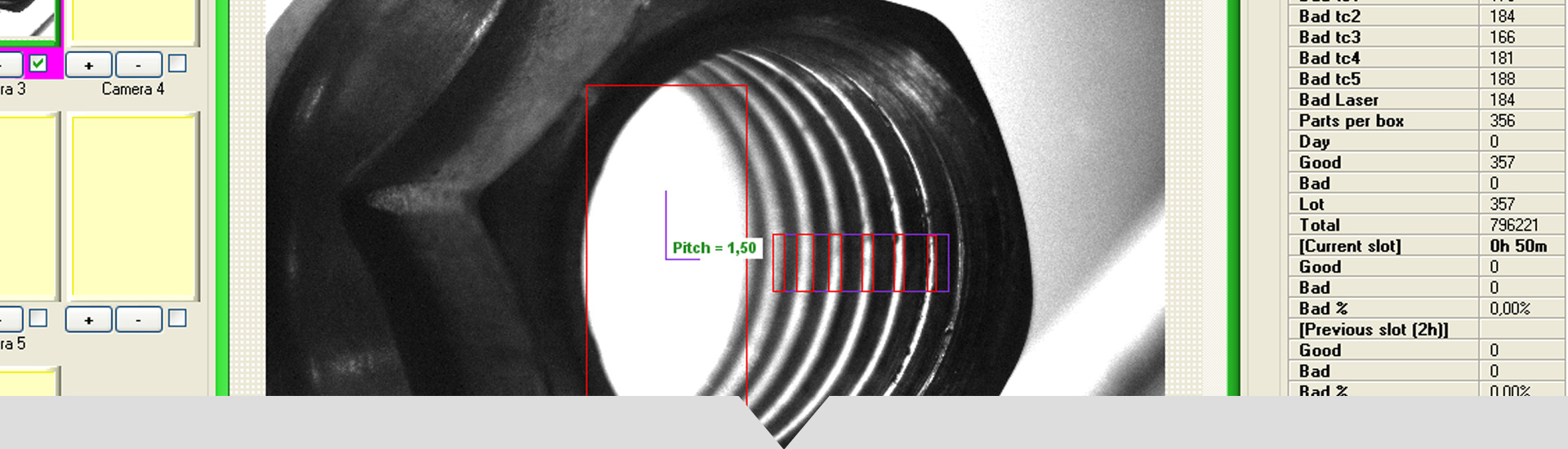

- Optical controls through Bi-telecentric Cameras.

With optical controls is possible to check every dimensional measure of every single piece with tolerances of ± 10 µm - Controls with Laser Caliper

We can evaluate specific parameters such as depth and recess with tolerances of ± 1 µm - 2D and 3D Laser controls

The 2D and 3D laser controls are used in special applications where it is necessary to assess the proper configuration of the piece as a whole.

CRACKS AND FLAWS

Avoiding cracks dents, bumps and other flaws is a key factor for an outstanding product. Through different types of analysis, the quality controls allow to identify on every piece the smallest flaw that could compromise its functionality. These Control Stations ensure automatically selected products with very tight tolerances and margins of error equal to zero.

The quality controls are carried out through:

Some of th quality controls that can be carried on are the following:

The quality controls are carried out through:

- Optical Controls with Bi-Telecentric and Pericentric Cameras

The optical inspection units allow to detect with great accuracy the presence of cracks, scratches, dents, burrs with an accuracy of ± 10 µm - Crack Controls with Eddy Currents with Eddy Currents Probe .

- Hardness Control Units with Eddy Currents Probe .

- Modal Analysis stations

Modal Analysis Stations are used where it is necessary to identify internal microfractures or weak points under surface.

Some of th quality controls that can be carried on are the following:

- Crack controls

- Hardness control

- Burr control

- Bumps control

- Coating Quality Contols (galvanic treatment, thermal coating, etc.)

- Double thread control

- Stem Rectilinearity

FUNCTIONALITY TESTING

Besides the standard controls our machineries can be equipped with stations dedicated to the mechanical testing and the assembly of compound mechanical pieces.

Mechanical testing Stations are:

Some of the Mechanical controls that could be carried on are :

Mechanical testing Stations are:

- Head recess depth Test with mechanical caliper and Torque measurement

Used to control size and quality of threaded holes. - Mechanical testing

Mechanical testing units are used to physically check the actual functionality of a component. - Assembly Units.

Assembly Units are installed to mount toghether a component made by different parts.

Some of the Mechanical controls that could be carried on are :

- Head Recess Depth

- Torque control for screwing/unscrewing

- Mechanical thread control

- Mechanical Functionality